Design Center

The Jinggong Mould Technical Center is an enterprise technical center certified by Jiangsu Province. It currently employs over 40 design and R&D personnel and has filed more than 50 patents for mould appearance design. The center is proficient in the requirements for mould design in the glass forming process and can develop designs based on samples or drawings provided by clients.

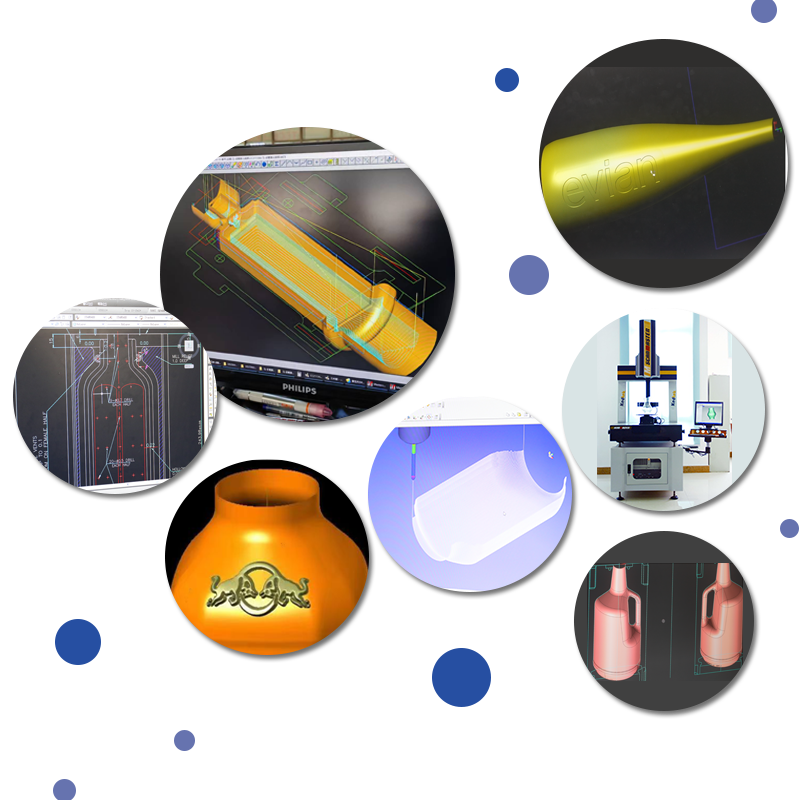

Design and R&D with UG Software:

1. 3D Modeling: Enhance the complexity and precision of mould design.

2. Mould Analysis: Conduct kinematic analysis to evaluate the structural stability of moulds, ensuring they meet actual production requirements.

3. Mould Processing Design: Plan tool paths and cutting parameters to improve mould processing efficiency and precision.

4. Mould Assembly: Carry out assembly checks upon design completion to ensure smooth assembly of all mould components and meet the actual operation requirements.

Quality Inspection Center

The Jinggong Mould Quality Inspection Center employs over 30 professional inspectors and is equipped with internationally leading high-end testing instruments such as spectrometers, mould capacity testers, 3D digital height gauges, and fully automatic coordinate measuring machines. All inspection data is uploaded to an information system, enabling quality traceability and thereby improving product quality.

Quality Control Process for Moulds:

1. Inspection of the implementation of the mould casting process standards.

2. Testing of material hardness and composition, and metallographic structure analysis for mould castings.

3. Quality inspection at every stage of the production process.

4. Final comprehensive quality inspection and report issuance.